The Role of IoT Applications in Real-Time Monitoring

Real-time monitoring forms the foundation of effective IIoT solutions. IoT applications bridge connected devices and the decision makers, allowing industries to collect, process, and analyze information real-time. Here’s how IoT applications make real-time monitoring possible:

Data Collection from Smart Sensors

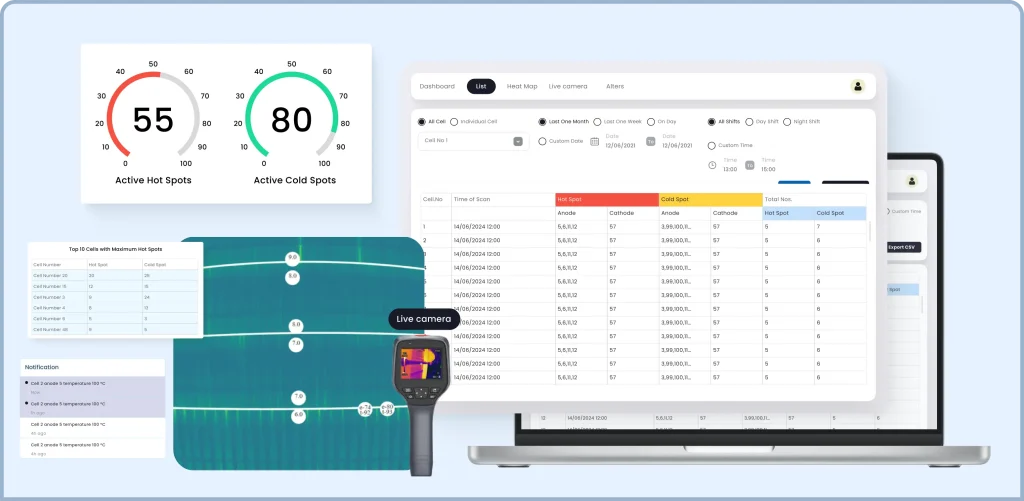

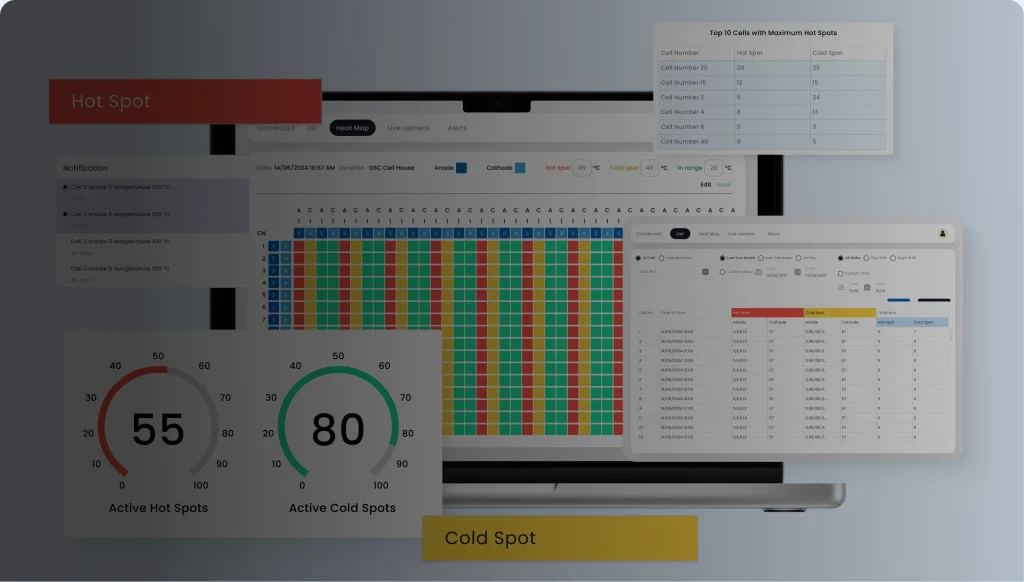

IoT applications interface with smart sensors installed on machinery, in production lines, or inside industrial environments. These sensors capture vital parameters, such as temperature, pressure, humidity, and vibration. IoT applications collate this data and allow for a centralized analysis.

No Gap in Communication Between Devices

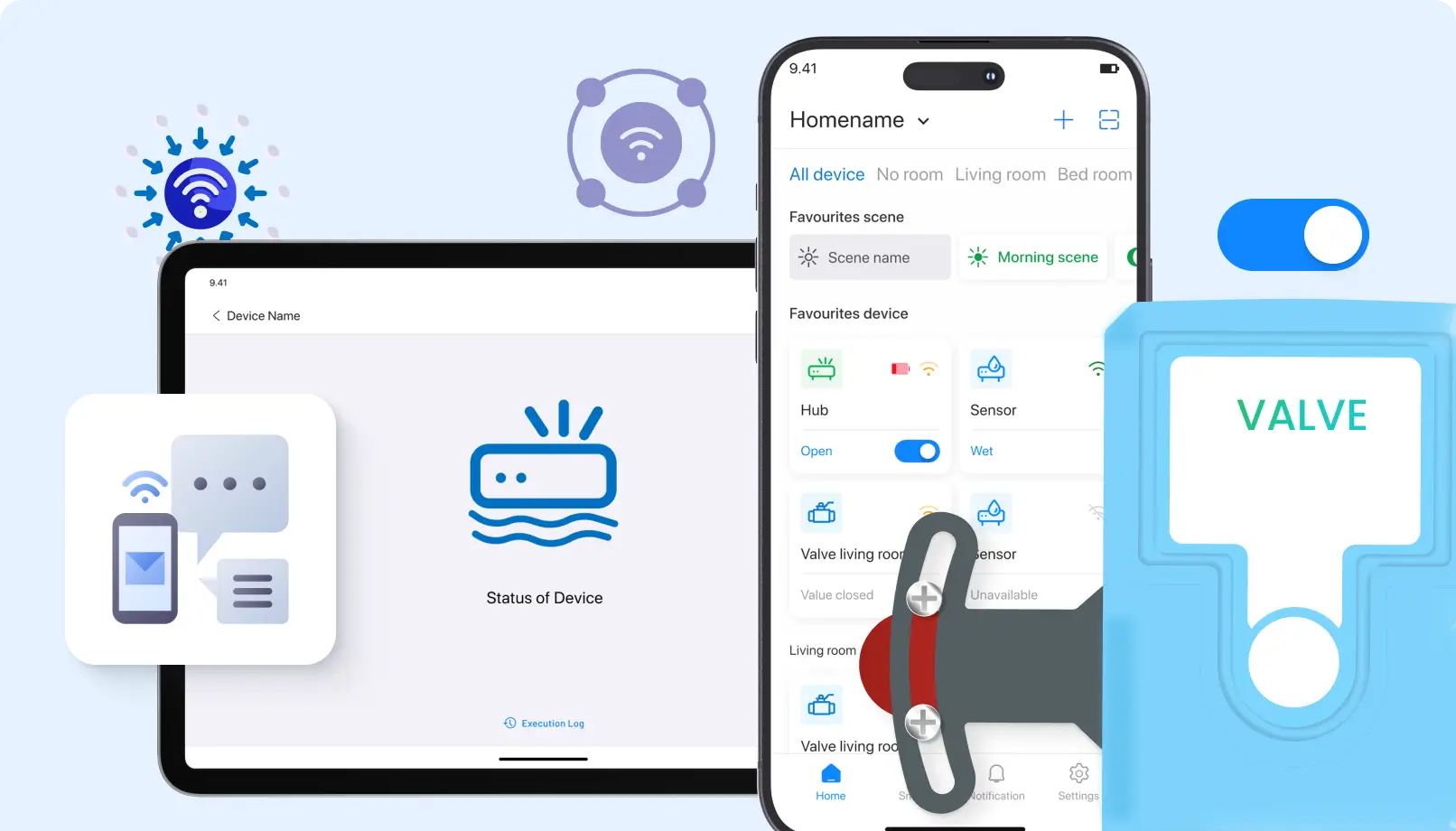

With the existence of IoT protocols such as MQTT, CoAP, and HTTP, IoT applications ensure that communication between devices is seamless. This allows the real-time transmission of data across cloud servers or even in edge devices where processing takes place.

Instant Alerts and Notifications

IoT applications are pre-built with algorithms to detect anomalies or thresholds. In case a sensor notices an unusual surge in temperature or pressure, the application would immediately alert the operator to allow swift intervention.

Enabling continuous data flow and analysis, IoT applications improve the visibility of operations and enable industries to take proactive steps towards challenges.

Key Benefits of IoT Applications in IIoT Solutions

IoT applications unlock a host of benefits for industries embracing IIoT solutions. Some of the key benefits are listed below:

1. Predictive Maintenance

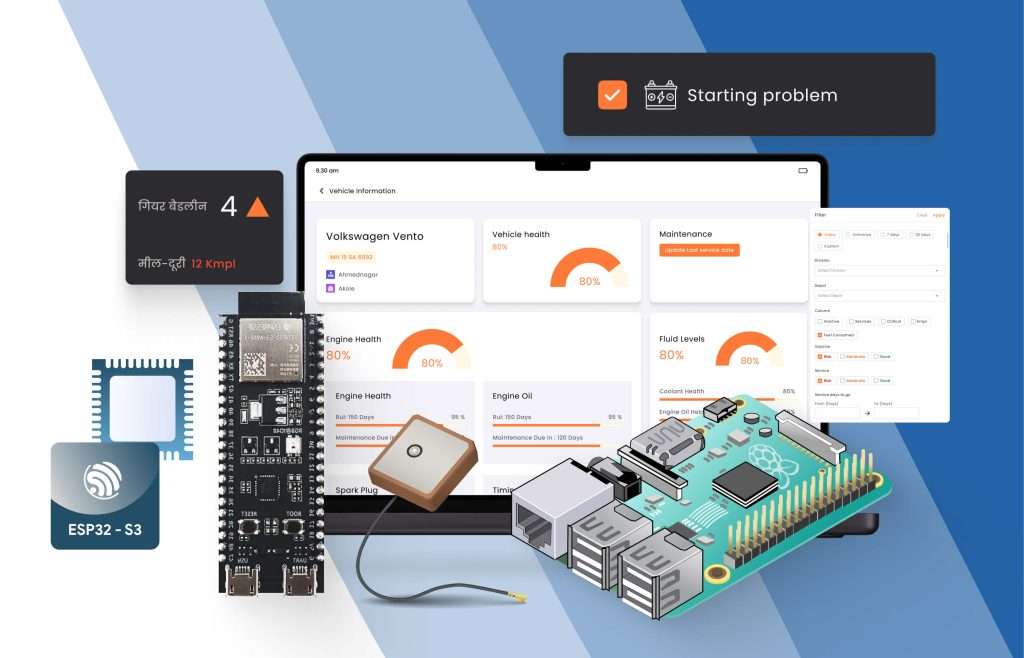

Traditionally, the maintenance techniques adopted are mainly reactive because they deal with problems only when they occur. IoT applications change this completely because it advocates for predictive maintenance. For instance, in terms of sensors positioned on machinery to identify wear and tear, IoT applications assess the details of this data to predict when the components will fail. This reduces downtime, minimizes costs, and increases equipment lifetimes.

2. Improved Operational Efficiency

IoT applications-based real-time monitoring allows industries to be able to identify bottlenecks in their operations. Using this data in production lines, companies are able to optimize workflows and reduce wastes while enjoying enhanced efficiency. For example, a manufacturing plant can modify its schedules according to demand and performance of the machinery in real time.

3. Safety Enhancement and Compliance

IoT applications help industries monitor safety parameters and ensure that they are compliant with regulations. For example, in chemical plants, IoT-enabled sensors can detect hazardous gas leaks and alert operators immediately. These applications may also generate reports to demonstrate compliance with safety standards.

Implementation of IoT Application Development for Real-Time Monitoring

Robust IoT application development will be the precursor to successful implementation of real-time monitoring for Industrial IoT solutions. Here are some key steps below:

1. Define Objectives and Use Cases

Before developing an IoT application, determine the specific objectives and use cases. For instance, do you want to track equipment performance, optimize energy consumption, or improve worker safety? That is, define clear goals so that your IoT application will be fit for business purposes.

2. Choose the Suitable Technology Stack

3. Merging of Cloud and Edge Computing

Real-time monitoring deals with enormous amounts of data. IoT applications have to depend on cloud and edge computing for efficient processing and analysis of the data. Cloud computing includes scalable storage and analytics capabilities. Latency reduction comes

from edge computing, which processes data nearer to its source.

4. Security and Scalability

Security is another important consideration while developing an IoT application. Use strong encryption, authentication, and access controls to protect industrial data of sensitive nature. Your application should also be scalable to scale with the growth.

Use Cases of IoT Applications in Real-Time Monitoring

IoT applications have revealed their worth across diverse sectors. Here are a few examples of use cases:

1. Manufacturing

IoE applications enable manufacturers to monitor production lines, track inventory levels, and maintain equipment health. Real-time data helps optimize workflows, reduces downtime, and makes better-quality products.

2. Energy Management

In the energy sector, IoE applications monitor power consumption and detect inefficiencies. For example, smart grids use IoE to dynamically balance energy supply and demand.

3. Logistics and Supply Chain

IoT application solutions do enhance visibility in logistics by tracking shipment. Sensors monitor real time-temperature and humidity, making sure even temperature-sensitive goods are transported safely.

Conclusion

Real-time monitoring is no longer a luxury; it’s now a necessity for companies that look to stay competitive. Through strong applications of IoT, companies will be able to transform their operations, improve efficiency, and unlock new levels of productivity. Whether predictive maintenance, improved safety, or energy optimization, the idea is boundless with IoT-powered solutions.