Understanding Industrial Communication Protocols

What are Industrial Communication Protocols?

Industrial communication protocols represent standardized rules of communication and interaction between the devices with an industrial environment. Those protocols introduce how data is forwarded and then received among the set devices; hence, a connection between different device manufacturers while still working effectively together. In industrial automation, it would be very important that machines such as sensors, controllers, and actuators forward information in real time to continue working efficiently.

Importance of Communication Protocols Industry

Usage of the communication protocol in industry allows:

Interoperability: It provides the capability of many devices from different manufacturers to work together.

Real-time Monitoring: Helps exchange data in real time is important for proper time decision making.

Reduced Downtime: Smooth communication helps in predictive maintenance that reduces the chance of any failure.

Cost Efficiency: Standardized protocols can reduce high costs of operation by making simple integration with the need for fewer proprietary solutions.

ModBUS: Introduction

What is ModBUS?

ModBUS is a serial communication protocol widely adopted in industrial automation. Developed by Modicon in the late 1970s, the ModBUS communicates between the different hardware connected to the same network. It is mainly used in SCADA systems.

Key Features of ModBUS

Master-Slave Architecture: ModBUS supports master-slave architecture in which one master device can address several slaves for communication, therefore making communication as well as data management less complicated.

Variations of Versions: ModBUS has numerous versions such as ModBUS RTU (Remote Terminal Unit), ModBUS ASCII as well as ModBUS TCP/IP. All these versions have different communication requirements by which communication could be either through a wire or without one.

Open Protocol: Since it is an open standard, anybody can develop this, ensuring compatibility across the highest devices.

Error Checking: It supports error checking with CRC (Cyclic Redundancy Check) to verify data integrity.

Applications of ModBUS

Process Automation: It is being utilized in oil and gas, chemical, and water treatment to watch and control processes.

Building Automation: Used in HVAC systems, which enable the communication between controllers and sensors.

Energy Management: Used in energy monitoring systems for reading data from meters and devices of power management.

CANBUS: What is CANBUS?

Controller Area Network (CANBUS) is a strong vehicle bus standard that allows microcontrollers and devices to be interlinked without a host computer. CANBUS was first conceived for automotive applications by Bosch in the 1980s, but due to its reliability and efficiency, it has also been applied in various industrial sectors.

Key Features of CANBUS

Multi-master Topology: CANBUS supports the multiple master protocol, allowing for many nodes to be producers and consumers, thus adding flexibility and message interchange redundancy.

High Speed Data Transfer: CANBUS supports high speed rate data transfer up to 1 Mbps. It is used in real-time applications.

Fault Tolerance: The design of CANBUS is such that it is fail operational. Even if one of the nodes fails, the network can be still functional, hence making it reliable at the communication channel.

Message Prioritization: In the context of CANBUS, the system is message prioritized wherein most critical messages are transmitted first. It is significantly prominent in applications involving time.

Applications of CANBUS

Automotive: This is widely used in modern day automobiles for interconnection among various control units such as the engine management unit or safety systems.

Industrial Automation: This is used in factory automation for the connection of sensors, actuators, and control systems reliably.

Medical Equipment: Used in medical equipment to ensure seamless communication between monitoring equipment and control systems.

Applications in Real Life

Smart Manufacturing

In smart manufacturing, organizations have become more dependent on IoT solutions to make it even more efficient. Through ModBUS, watch the process in real-time for communication with the sensors, controllers, and SCADA systems for manufacturers. For example, a plant will have ModBUS monitoring data from the temperature sensors on the production lines. There is immediate adaptation to optimal conditions. Automotive Diagnostics.

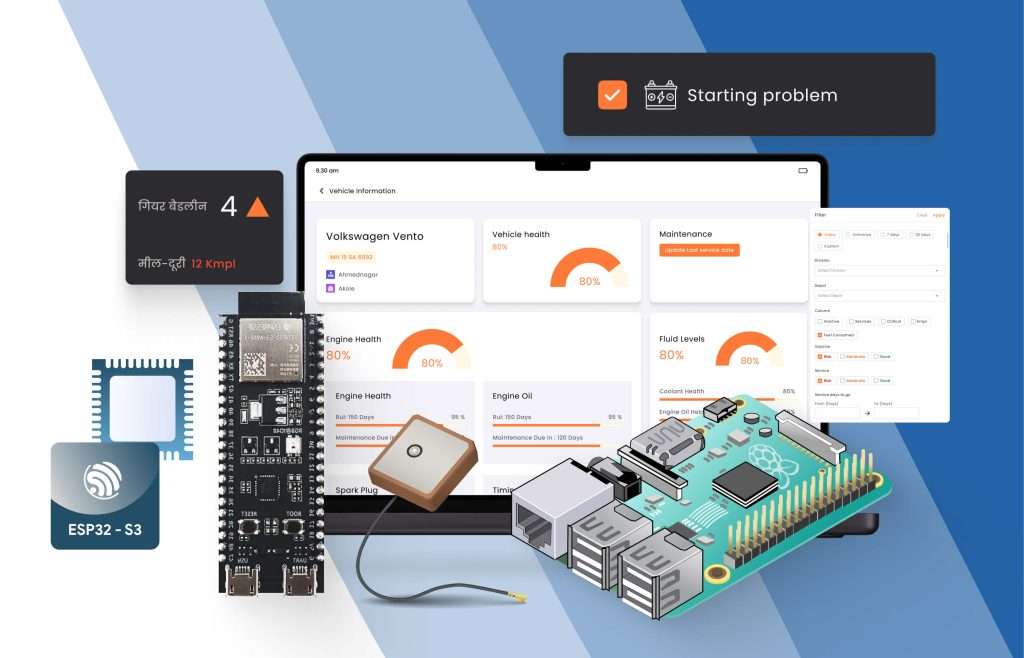

CANBUS technology is the heart of diagnostics in modern cars. Mechanicians can attach a diagnostic system to a vehicle’s CANBUS and extract data from a number of control units. The ability brings about quicker detection of faults, thus shortening repair times, reducing the unreliability and making the vehicle more reliable. More than this, this software will enable the development of ADAS depending on real-time data coming from various sensors.

Building Automation

In building automation, integration of ModBUS with HVAC systems enables energy management with reduced frictions. The facility managers will be able to monitor and control energy consumption using ModBUS for communication purposes among thermostats, sensors, and control systems, thereby reducing operational cost and providing more comfort for the occupants.

Industrial Robotics

Another widespread application of CANBUS is in robotics, in which it provides connectivity between the different parts of a robot, including motors and sensors. This makes the robotic system perform complex operations with a high degree of accuracy and reliability for trouble-free manufacturing and logistics operations.

Industrial Communication Future Trends

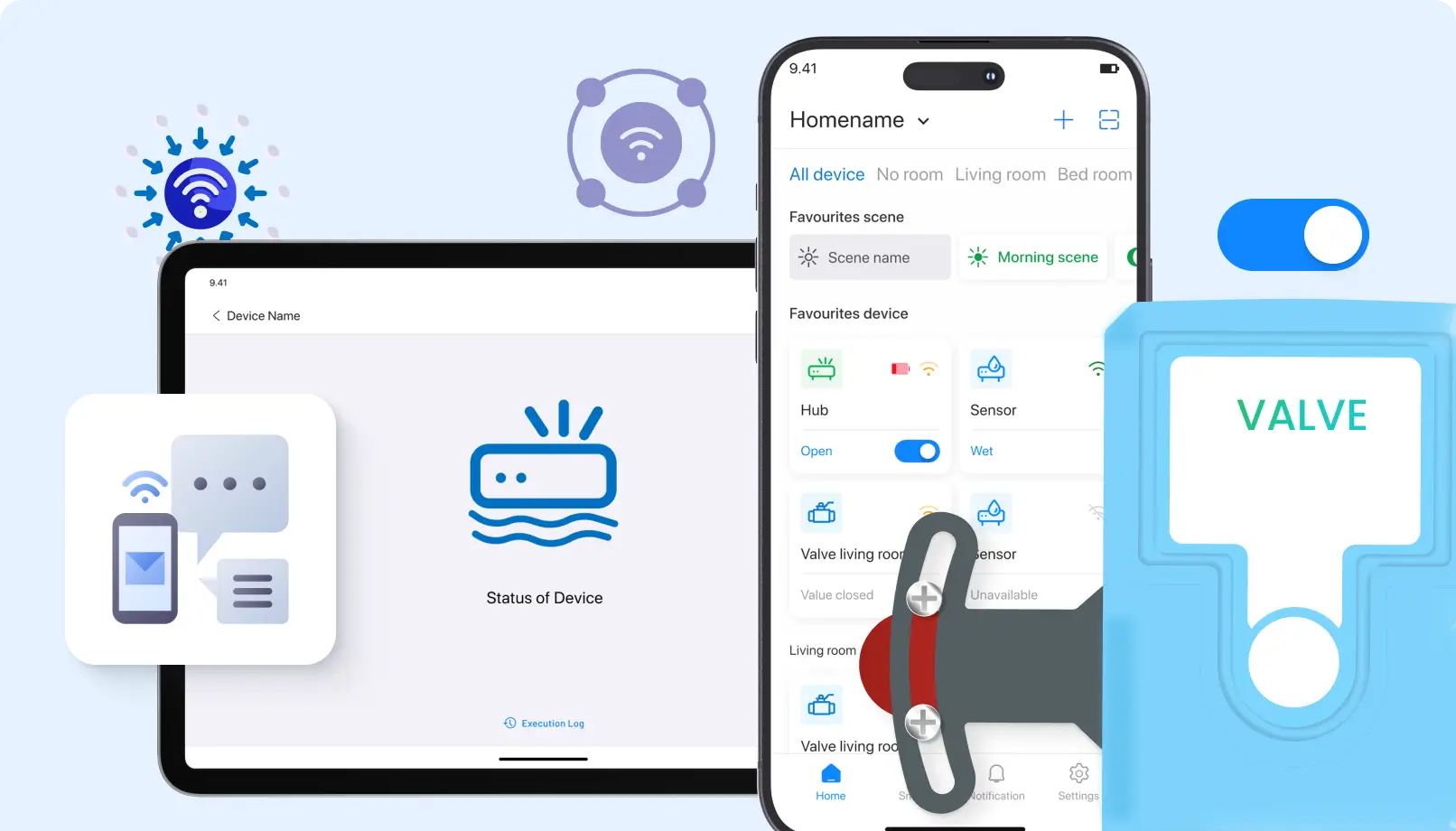

1. Integration with the Internet of Things

More industries will use IoT, which means their integration with ModBUS and CANBUS into the IoT platform will be highly in demand because such convergence may ease the real-time data analytics as well as predictive maintenance and provide a more important decision-making process.

2. Enhanced Security Measures

More and more threats are viewed through cyber attacks; hence, the future in communication protocols is absolutely essential, and hence, ModBUS and CAN BUS would be developed with stronger security features to avoid unauthorized access to any data and against human error.

3. Support for Advanced Applications

Such emerging technologies such as AI and ML will increase the needs for advanced communication protocols. The later versions of ModBUS and CAN BUS may inherit features or enhancements that support analytics and automation based on AI.

Conclusion

The most commonly used communication protocols for streamlining industrial communications entail a robust way towards operational efficiency and reliability in an industrial environment experiencing the fastest pace. ModBUS, CANBUS provides robust solutions to otherwise diverse communication needs across various sectors. One can make sure seamless interoperability, reliability, and cost-effectiveness in operations by using them.

The more the industries change, the more their role of these effective communication protocols like ModBUS and CAN BUS is going to increase in the future. Adoption of these technologies will unlock organizations’ real power of automation to achieve a networked world with improved efficiency.