Enrisk

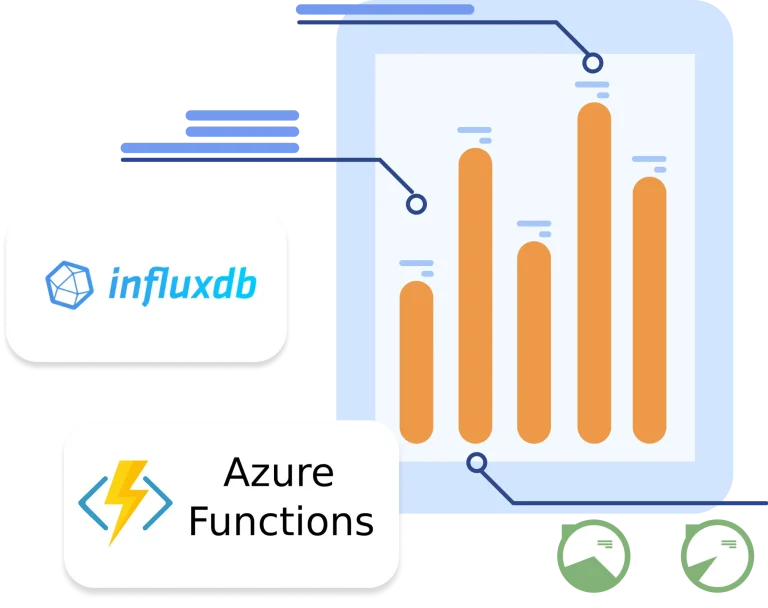

At the heart of Enrisk is a robust cloud-connected infrastructure leveraging Azure IoT Hub, Azure Functions, InfluxDB, and Grafana. Field-deployed laboratory instruments interface with a local gateway, which collects and transmits real-time data. Azure’s serverless architecture (Functions) ensures scalable and event-driven data processing.

Looking for a Smart Device to develop?

Share at:

About Enrisk

Enrisk empowers enterprise and industrial clients to mitigate operational and equipment-related risks through connected IoT ecosystems. For the oil sector, instruments deployed in the field are connected via gateways that transmit data to the cloud through Azure IoT Hub. Azure Functions process this incoming data, extracting key measurement values and writing them to InfluxDB, which is visualized through Grafana dashboards for system-wide analytics. At various stages, the data is filtered and cleaned, and changes it’s state from Bronze, Silver to Gold. Entire fleet monitoring and maintenance of the gateways was undertaken through Mender dashboard.

Features & Purpose Of

This Application

Real-time data from laboratory instruments is securely transmitted to Azure via IoT Hub, enabling scalable and reliable cloud connectivity.

Real-time data from laboratory instruments is securely transmitted to Azure via IoT Hub, enabling scalable and reliable cloud connectivity.

Azure Functions process incoming telemetry, extract vital measurements, and store them in InfluxDB for high-performance time-series analysis.

Azure Functions process incoming telemetry, extract vital measurements, and store them in InfluxDB for high-performance time-series analysis.

Grafana dashboards offer real-time visualization of system health, equipment performance, and risk insights across deployed devices.

Grafana dashboards offer real-time visualization of system health, equipment performance, and risk insights across deployed devices.

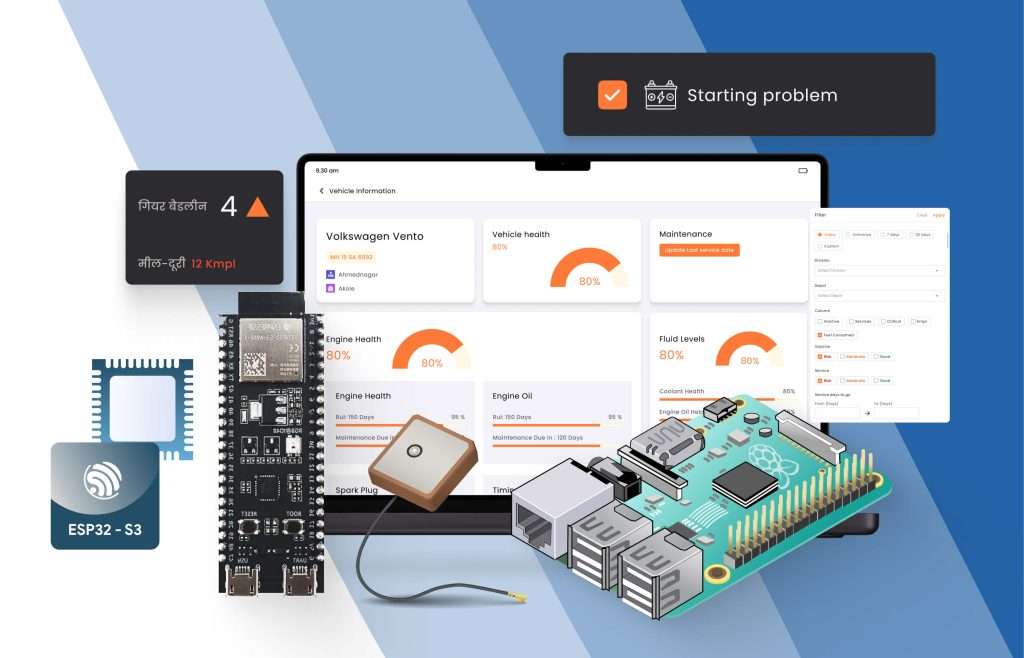

Industrial equipment health is monitored continuously to forecast maintenance needs and prevent unexpected failures.

Industrial equipment health is monitored continuously to forecast maintenance needs and prevent unexpected failures.

The gateways had multiple connectivity options from Ethernet, Wifi, LTE or a combination of them with failover mitigation.

The gateways had multiple connectivity options from Ethernet, Wifi, LTE or a combination of them with failover mitigation.

The gateways underwent robust OTAs through Mender, along with fleet monitoring and remote troubleshooting.

The gateways underwent robust OTAs through Mender, along with fleet monitoring and remote troubleshooting.