1. Internet of Things (IoT)

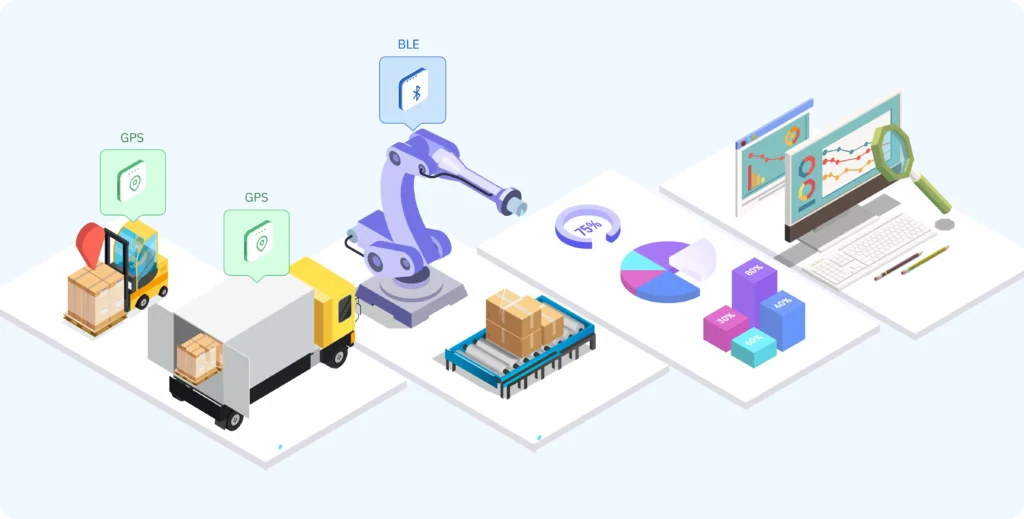

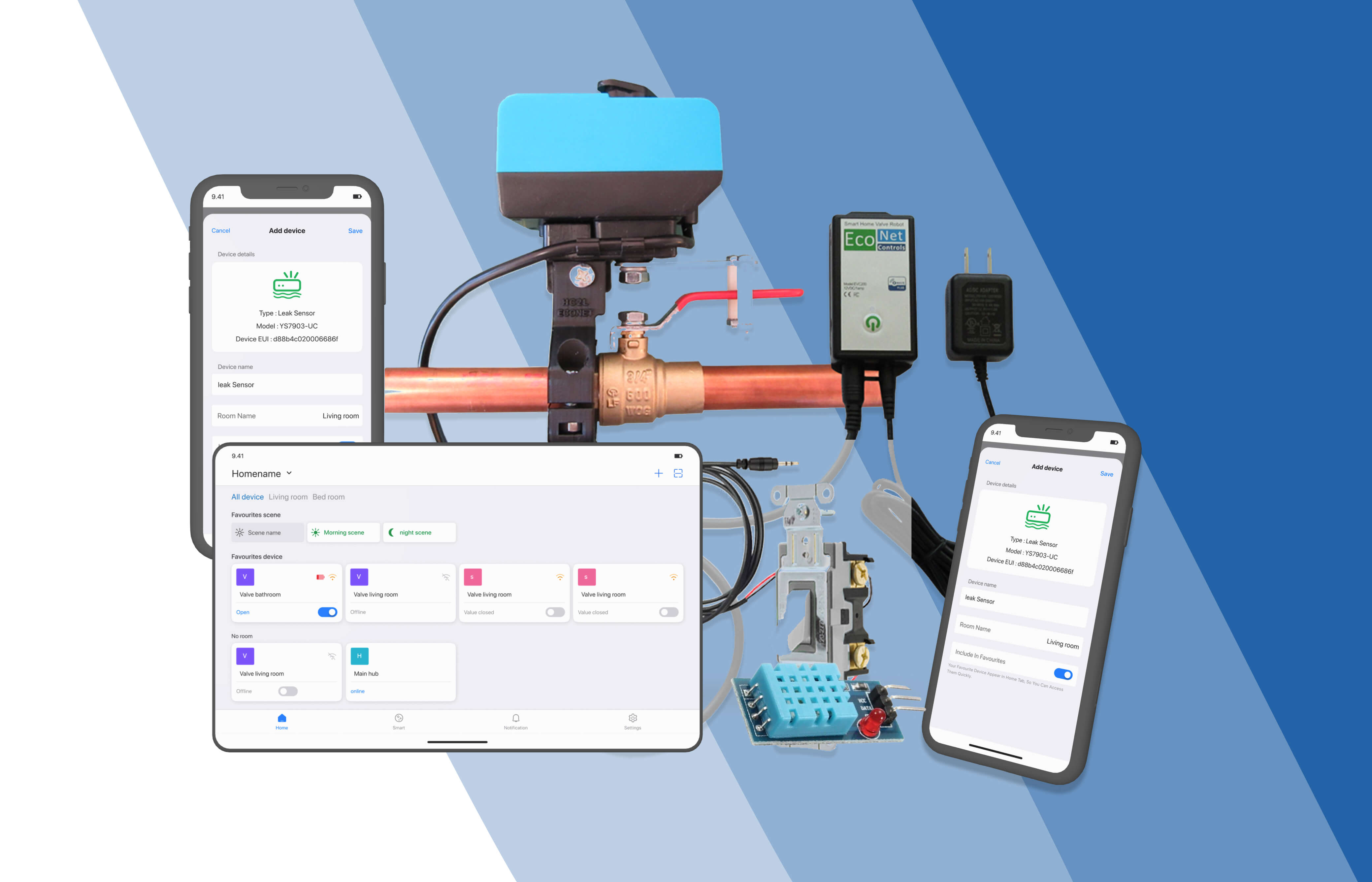

IoT is the backbone of every smart factory. Sensors, tags, and gateways continuously capture data from machines, materials, and people—transforming the production floor into a connected network of intelligent nodes.

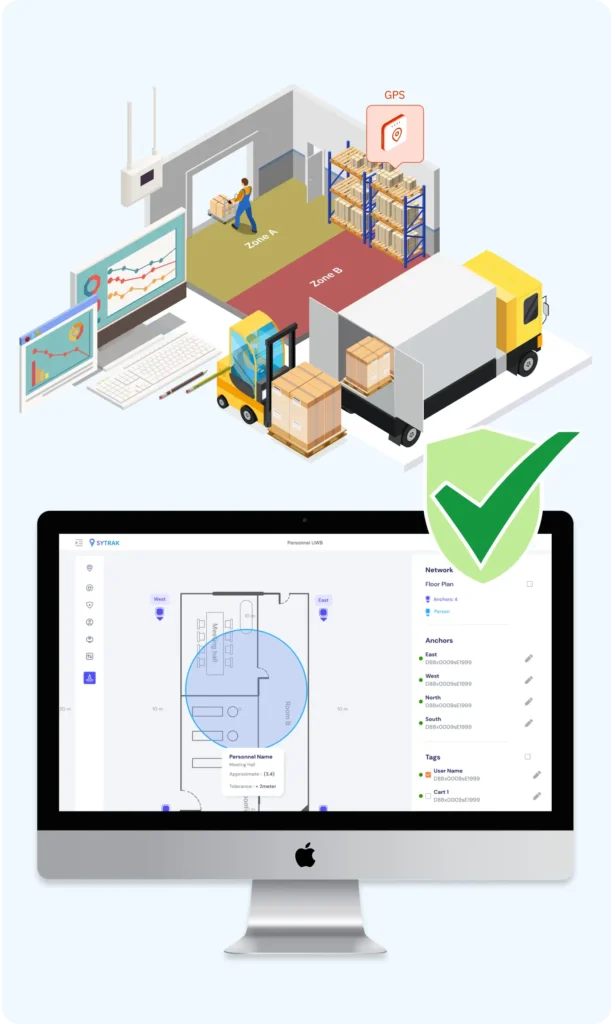

With platforms like SYTRAK, this data is transformed into actionable intelligence—helping manufacturers monitor asset health, predict maintenance needs, and track movement in real time, both indoors and outdoors.

Key Advantage: Real-time visibility and data-driven decision-making.

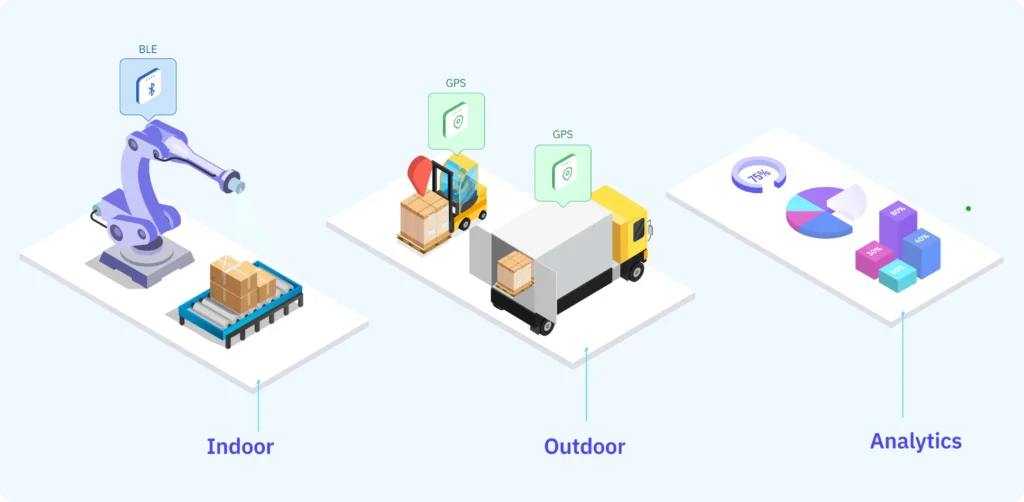

2. Industrial Automation & Robotics

Automation brings speed and consistency to production. From robotic arms to automated guided vehicles (AGVs), modern factories rely on machines that can perform repetitive tasks with minimal error.

When combined with IoT insights, automation becomes even smarter—machines can respond dynamically to real-time changes in demand or equipment status.

Key Advantage: Increased productivity and precision with reduced human error.

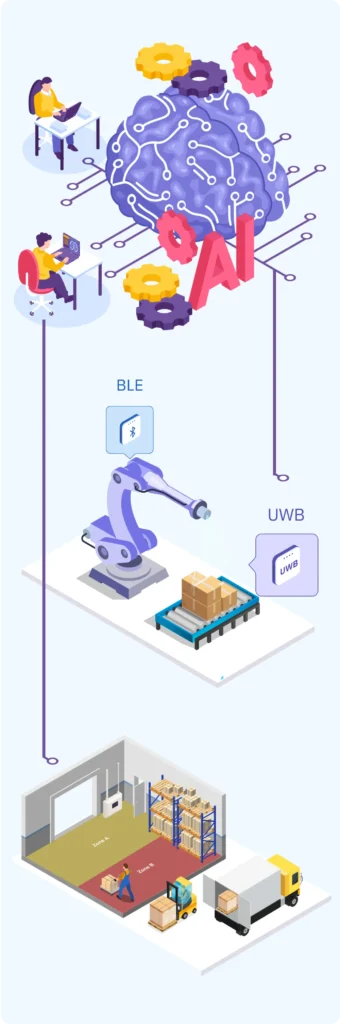

3. Artificial Intelligence & Machine Learning (AI/ML)

AI and ML take smart manufacturing to the next level by enabling predictive and prescriptive intelligence. These algorithms analyze historical and live data to uncover patterns—anticipating equipment failures, optimizing energy usage, and even recommending process improvements.

SYTRAK integrates with AI models to identify operational anomalies and efficiency gaps before they impact production.

Key Advantage: Predictive analytics for proactive decision-making.

4. Digital Twins

A digital twin is a virtual replica of a physical asset, process, or system. It allows manufacturers to simulate operations, predict outcomes, and test “what-if” scenarios—without interrupting real-world workflows.

By linking IoT data from SYTRAK with digital twins, manufacturers can visualize the entire production ecosystem and plan improvements with confidence.

Key Advantage: Continuous optimization through virtual modeling.

5. Cloud Computing & Edge Processing

Smart factories rely on vast amounts of data. Cloud platforms provide the scalability and computing power needed to store, analyze, and visualize this information. Meanwhile, edge computing brings computation closer to the source—ensuring low-latency decision-making even in remote or time-sensitive environments.

SYTRAK leverages both approaches to deliver fast, secure, and scalable data orchestration for enterprises of all sizes.

Key Advantage: Speed, scalability, and secure data access across locations.

6. Cybersecurity & Data Protection

As factories become more connected, they also become more vulnerable to cyber threats. A strong security framework is essential to protect operational data and ensure business continuity.

SYTRAK incorporates end-to-end encryption, access control, and tamper alerts to safeguard both data and assets—reinforcing trust in every connected system.

Key Advantage: Secure and compliant digital infrastructure.

7. Advanced Analytics & Visualization

Data by itself is not power—insight is. Advanced analytics convert complex data streams into meaningful dashboards and KPIs. SYTRAK’s analytics layer offers intuitive visualizations that empower decision-makers to identify patterns, spot inefficiencies, and take targeted action.

Key Advantage: Simplified visibility for faster, smarter decisions.

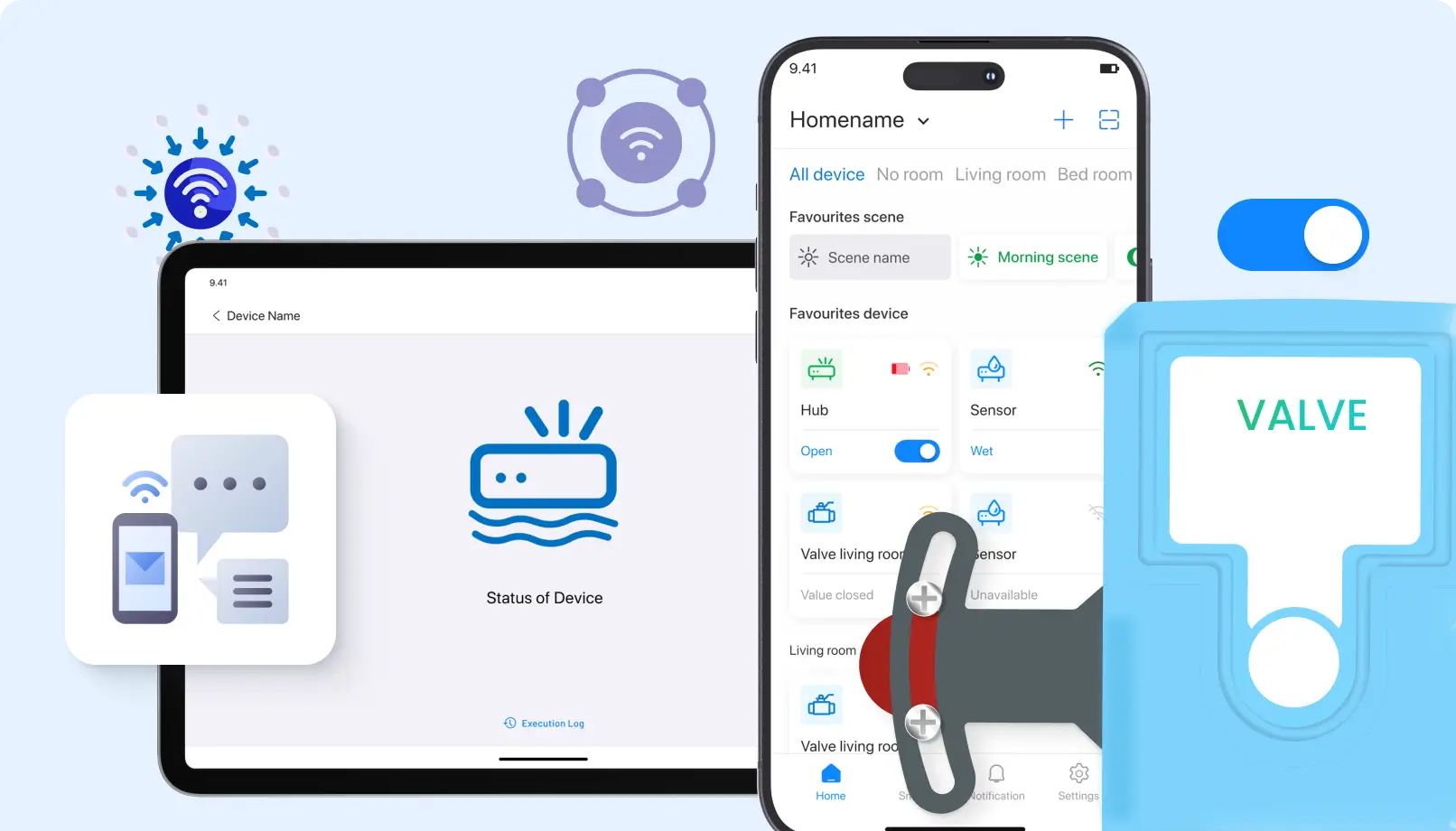

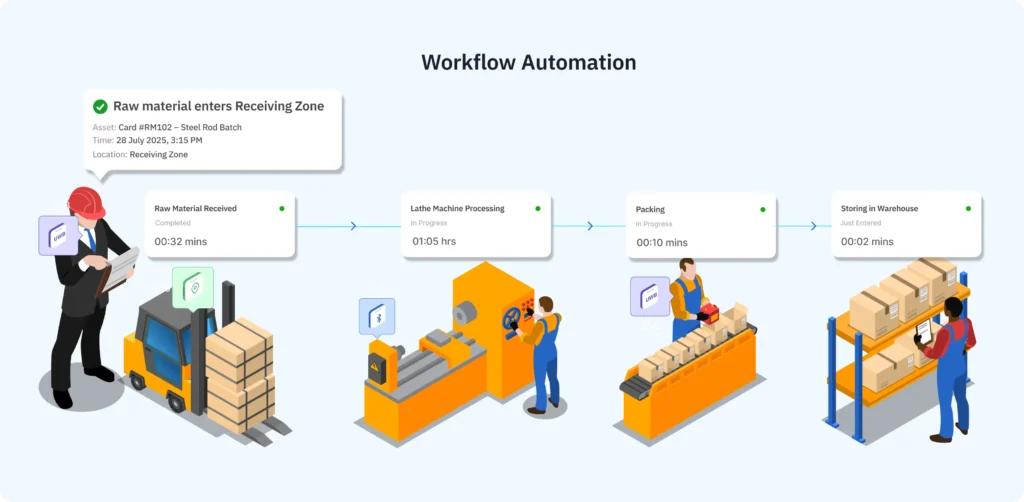

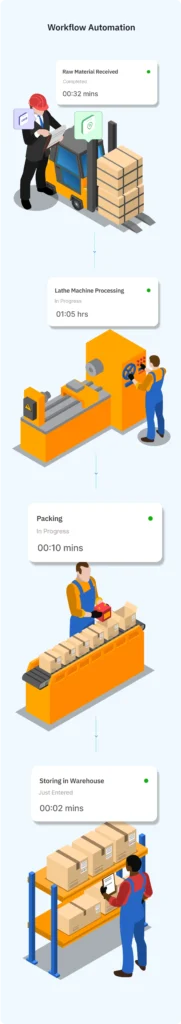

8. Connectivity Technologies (BLE, UWB, GPS, 5G)

Reliable connectivity is the lifeline of smart factories. Technologies such as Bluetooth Low Energy (BLE), Ultra-Wideband (UWB), GPS, and 5G ensure uninterrupted data flow between assets and systems.

SYTRAK intelligently integrates these technologies to deliver seamless indoor and outdoor tracking—ensuring no blind spots in asset visibility.

Key Advantage: Seamless communication across environments.

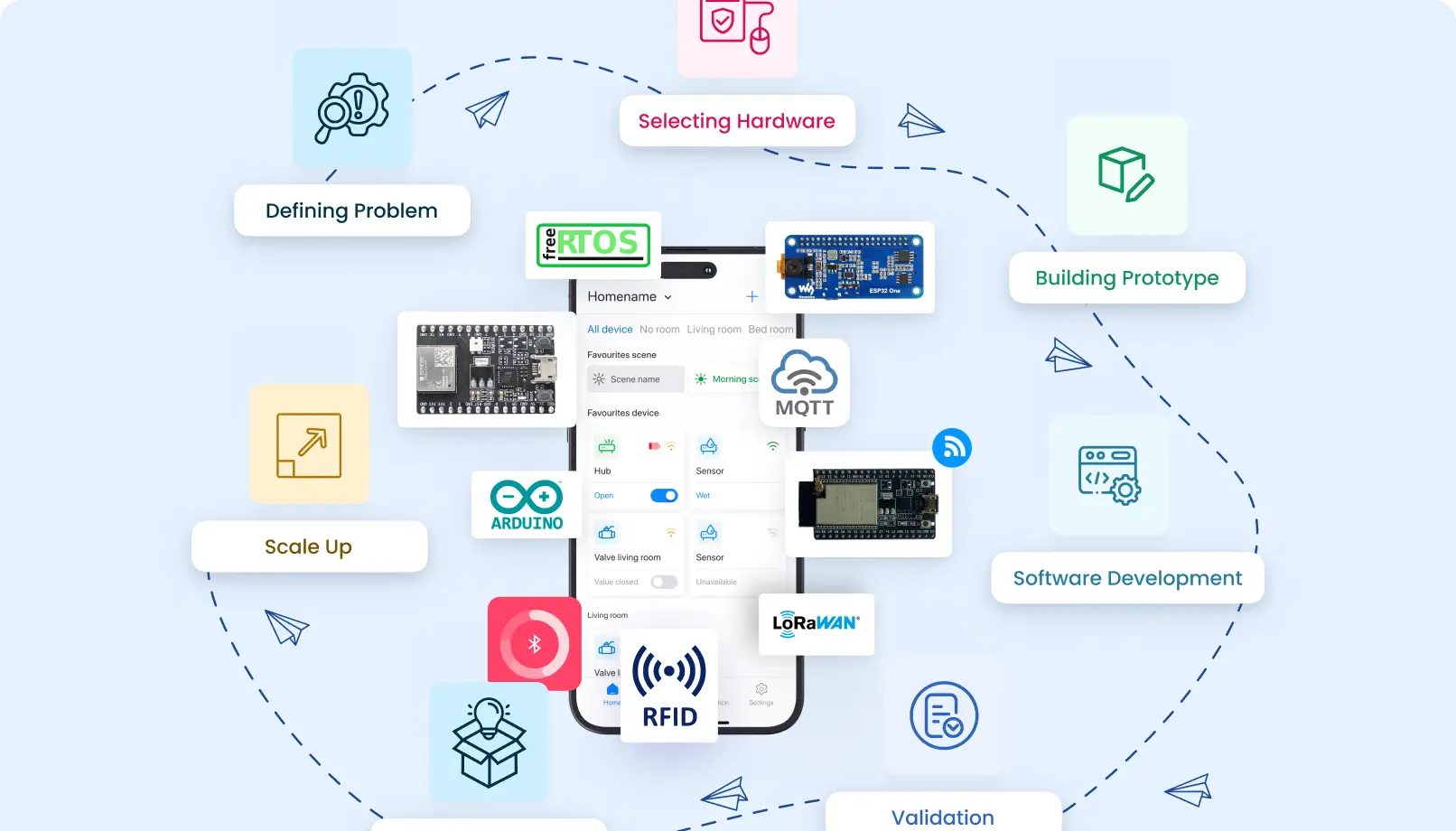

The Krishworks Vision

At Krishworks Technology Innovations, our mission is to simplify the complex. With SYTRAK, we bring together IoT, AI, and automation into one unified orchestration platform—helping industries move beyond monitoring toward intelligent coordination.

Because in the smart factory of tomorrow, efficiency isn’t just measured—it’s orchestrated.

In Summary

The technologies driving smart factories—IoT, AI, robotics, cloud, and more—are not isolated innovations. Together, they form the digital nervous system of modern manufacturing. Platforms like SYTRAK unify these technologies to provide clarity, control, and foresight—empowering manufacturers to know where everything is, how it’s performing, and what comes next.