Myro Paintbot

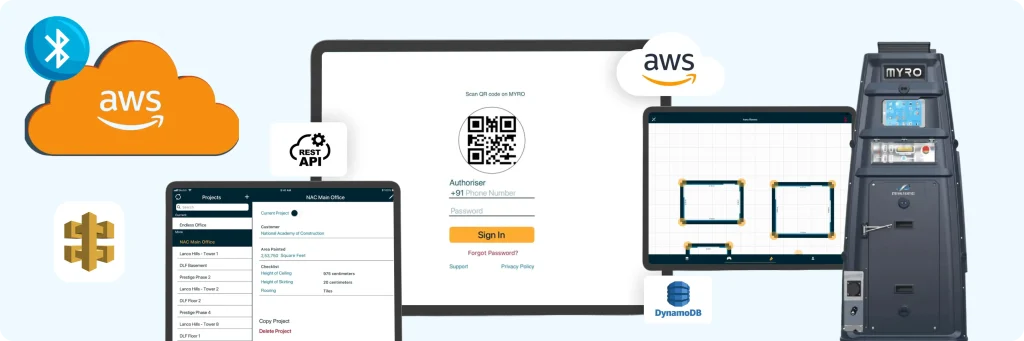

A Singapore-based startup partnered with us to develop a mobile app for Myro, the world’s first intelligent wall-painting robot created by Eternal Robotics. The goal was to build a centralized control and management app that could revolutionize labor-intensive painting processes through automation

Location

Singapore

Clients

Eternal Robotics

Project Duration

2 months

Industry

Construction & Industrial Automation

Services Provided

Architecture Engineering

Designed a scalable and modular system integrating BLE communication, mobile control, and AWS cloud services.

UI/UX Design

Crafted an intuitive multi-tab interface to manage robotic painting workflows, with a focus on usability for non-technical operators.

Mobile App Development (iOS & Android)

Built using React Native, enabling cross-platform deployment on iPads and Android tablets.

Back-end Development

Developed RESTful APIs using AWS Lambda and API Gateway for secure, low-latency communication between devices and cloud.

Cloud Infrastructure Setup

Deployed a robust cloud backend using AWS managed services including DynamoDB, S3, and Cognito.

Bluetooth Low Energy Integration

Engineered a custom BLE module to handle scanning, pairing, data transmission, and error handling for robot-device communication.

Quality Assurance

Comprehensive testing including device simulation, BLE stress tests, and usability validation for real-world painting operations.

Technical Consulting & Product Management

Collaborated closely with client teams from Singapore and India to ensure requirements were met with industrial-grade reliability.

Technologies Used

Frontend

- React Native (Cross-platform mobile development)

- JavaScript / TypeScript

- Redux (State Management)

Communication & Protocols

- Bluetooth Low Energy (BLE) – Custom L2CAP COC-based messaging for robot control

- MQTT (For AWS IoT integration in future scope)

Backend & Cloud

- AWS Lambda – Serverless logic execution

- Amazon API Gateway – RESTful API exposure

- Amazon DynamoDB – Fast, scalable NoSQL database for user and project data

- Amazon S3 – Storage of floor plans and layout assets

- AWS Cognito – Secure user authentication and authorization

- AWS CloudWatch – Monitoring and logging

DevOps & Deployment

- AWS CodePipeline / CodeBuild – CI/CD automation

- AWS IAM – Secure access control

- AWS CloudFormation – Infrastructure as Code (IaC)

Challenges

- Manage entire painting projects from a tablet device (iPad-first UX)

- Interface with robotic hardware using low-latency Bluetooth Low Energy (BLE)

- Offer real-time operational control with minimal user friction

- Store and sync project and user data securely and scalable in the cloud

- Ensure future-proof deployment across multiple users and devices

Solution Overview

The MyroPaintbot mobile application was built using React Native to support cross-platform deployment (iOS and Android). The architecture comprises three major components:

1. Mobile Client (Edge Interface)

- Built in React Native with a modular structure

- BLE communication layer enables pairing, command control, data sync, and error reporting with the Myro robot

Organized UI with four main modules:

- Project Management

- Live Robot Control

- Floor Plan Editor

- User Settings & Profile

2. AWS-Backed Cloud Backend

- Amazon DynamoDB: Structured storage for high-speed, NoSQL access to project data, floor layouts, and robot configurations

- Amazon S3: Scalable file storage for user-uploaded content

- REST APIs: Hosted on AWS to support data sync, user actions, and configuration pulls

3. Developer Tools & Testing Interface

- Command suite interface for executing and testing robot instructions such as movement, spray initiation, system calibration, etc.

- BLE channel management for handling reconnections, error recovery, and task execution

How It Works

1. Draw & Define:

The operator draws a digital floor plan, adds spatial references, and defines wall boundaries.

2. Plan & Schedule:

Painting tasks are planned based on the layout and scheduled for execution.

3. Operate & Monitor:

Commands are sent via BLE, and progress is monitored live.

4. Debug & Optimize:

Built-in tools allow testing all robot commands for precision and reliability.

Results & Business Impact

By combining BLE-based robot control, cloud-powered data management, and an intuitive mobile UI, MyroPaintbot enabled :

- 70% reduction in on-site manual labor

- Full remote control and monitoring of painting projects from a tablet device

- Scalable user management and data storage via AWS DynamoDB and S3

- Rapid time-to-market, thanks to AWS-managed backend services

- Robust field debugging tools for real-time operational support

This solution transformed traditional interior finishing operations into a modern, robotic, and cloud-connected workflow, demonstrating how AWS cloud infrastructure can enable innovation even in physically intensive industries.

Why AWS

We selected Amazon Web Services (AWS) to power the backend infrastructure due to its

- Scalability to support multiple concurrent robot deployments and user projects

- Security features including IAM and encrypted REST APIs

- Fully managed services that reduced time-to-market and operational overhead

Key AWS Services Used

Service

Purpose

Amazon DynamoDB

To store project metadata, user profiles, and app configurations with millisecond response times

Amazon Cognito

For storing user-generated assets like floor plans and resource files

Amazon Cognito

For secure authentication and access control

AWS Lambda + API Gateway

For stateless REST API handling and business logic execution