1. Real-time GPS tracking

Use case: Delivery fleet route optimization

Real-time GPS tracking will allow fleet managers to track vehicles at the exact location in real-time and change the routes in real-time to improve the efficiency and shorten delivery times. It is highly helpful for an industry like e-commerce or logistics, where timely delivery is the essence.

Example: An e-commerce giant uses GPS sensors fitted into its delivery trucks to track truck location. In case of unexpected traffic congestion, the fleet management system alters the route of the trucks so as not to cause delay. This way, the deliveries are done on time. Real-time tracking also tracks the status of delivery to the customers.

Use Case: Reduce Idle Time

GPS sensors also track when vehicles are idling for a more extended period, which contributes towards enhanced fuel consumption and delays.

Example: A waste management company realizes that certain garbage trucks spend a long time waiting in routes. The fleet manager employs the data from GPS tracking analysis of idle times and readjusts routes or schedules to reduce downtime, thus decreasing the amount of fuel consumed and enhancing operational efficiency.

2. Fuel Monitoring and Optimization

Use Case: Fuel Theft Prevention

In return, fuel sensors also provide real-time consumption tracking, which alerts the fleet manager to potential irregular fuel usage, possible cases of unauthorized use or theft.

Example: A logistics company uses fuel monitoring sensors to identify discrepancies in fuel usage. Once it finds unusual fuel consumption in one of the trucks, it notifies the fleet manager. After verifying, it found that the driver had been stealing fuel, and the company took the required corrective measure so that such losses could not be made in the future.

Use Case: Optimization of Fuel Efficiency

Monitoring fuel usage will be able to provide fleet managers with real-time data on which decisions can be made in order to improve fuel efficiency. Sensors will also warn you about leaking fuel or inefficient driving behaviors, which are good examples of wasteful behavior regarding fuel.

Example: A transportation company installs fuel gauges on all their vehicles. The analysis of data collected reveals that some vehicles are consuming a lot of fuel compared to others when conveying the same routes. Analysis further shows that these drivers press the clutch mostly and brake hard, making it inefficient. The company trains the drivers on how to reduce harsh acceleration and braking efforts, which later makes all the difference in saving fuel.

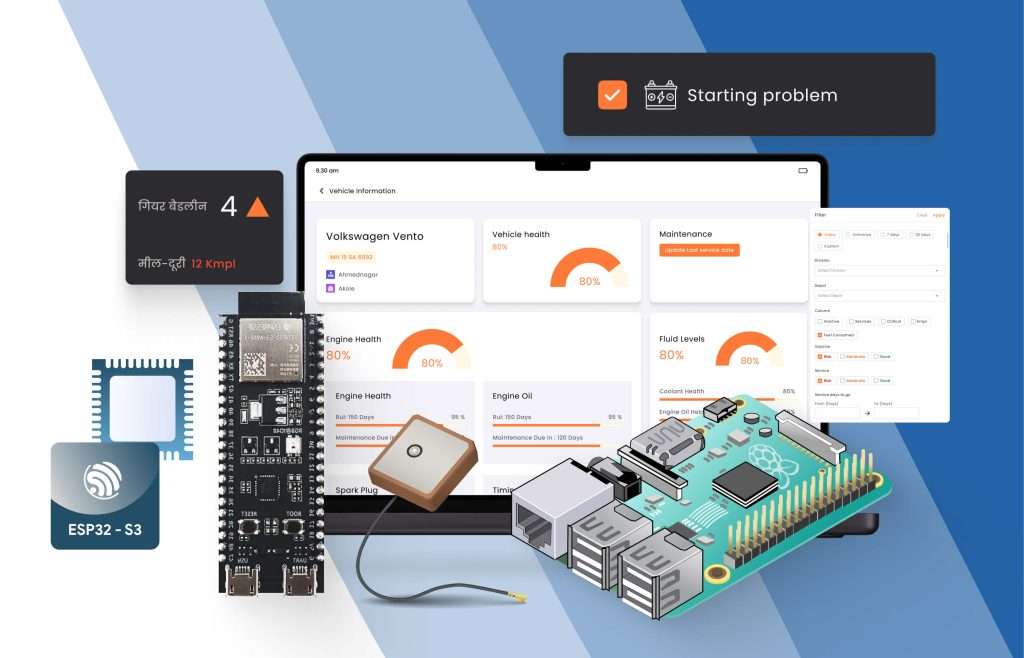

3. Predictive Maintenance

Use Case: Avoiding Engine Failure

Sensors keep track of all the critical parameters, such as engine temperature, oil pressure, and the overall health of a vehicle. In case some anomalies are found or a component is about to reach its useful end, it sends out warning signals for maintenance before the failure occurs.

Example: A trucking company is using IoT sensors to monitor engine performance fleet-wide. One vehicle has an overheating indication, and the predictive maintenance system flags it for examination. The company schedules to replace a cooling fan that has failed before an engine fails catastrophically in the field and causes delays or higher repair costs.

Use Case: Tire Pressure Monitoring

Tires must have their pressure maintained appropriately in any vehicle for safety and fuel efficiency. The pressure sensors will monitor in real-time and alert drivers or fleet managers when there are problems that need to be addressed promptly.

Example: A delivery company installs tire pressure sensors in the fleet cars. On a routine delivery run, one of the sensors identifies that one of the tyre pressures is critically low. The system reports an alert to the driver and the fleet manager so that the vehicle can be stopped safely and the tyre re-established before the tire entirely bursts, thus preventing a potential accident and saving tyres from further wear, too.

4. Driver Behavior Monitoring

Use Case: Reduced Risky Driving

Different driver behavior including high speed, jerky braking, hard turns, or acceleration is monitored by the sensors. This information will be used by fleet managers in identifying drivers that exhibit risky behaviors and serve to train them in safe practices.

Example: A taxi company use driving behavior sensors to monitor its drivers. Data shows that some of the taxis are driving habits to excessively speeding and braking. The company institutes a driver safety program to curb those habits, resulting in fewer accidents, lower insurance premium, and safer roadways for the taxis’ passengers and other drivers.

Use Case: Real-Time Driver Feedback

Some sensor systems provide feedback on real-time occurrences like speeding, abrupt braking, or acceleration. This type of feedback improves driving habits and enhances road safety.

Example: An example would be, a logistics company installing sensors onto its trucks, to instantly feed back information to the drivers when they over-speed or make sharp turns. Over time, this real-time feedback would improve their driving behavior, reducing accidents and at the same time improving the vehicle’s fuel efficiency, as driving will be much smoother.

5. Asset Tracking

Cargo Monitoring for High-Value Goods

Assets employed for the transportation of high-value or sensitive cargo are monitored by asset-tracking sensors to evaluate the condition and location of the cargo in real-time. It ensures goods are safe and lowers the threat of theft or damage.

Example: An expensive electronics shipment with asset-tracking sensors emitting real-time location information for each cargo unit. A fleet monitoring manager is immediately notified when such a shipment deviates from the scheduled route and contacts the driver to learn what might have happened. The timely intervention can prevent theft and ensure safe delivery.

Use Case: Monitoring of Perishables by Cold Chain

Cold-chain logistics is sensitive to the right temperature and humidity levels. There are environmental sensors that measure the refrigerated truck environment; this ensures that perishable foods or pharmaceuticals are transported at the optimal conditions required.

Example: A pharmaceutical company is making use of temperature sensors in the refrigerated trucks used for transporting vaccines. The sensors monitor the truck’s interior temperature; if it exceeds a permissible limit, the system alerts the driver and fleet manager. The driver is then sought to take appropriate measures and perhaps stop the truck for immediate servicing to maintain vaccine integrity during transportation.

6. Environmental Monitoring

Use Case: Cold Chain Logistics for Food Safety

Environmental sensors provide the appropriate temperature and humidity requirements for the most perishable products, including fresh produce, dairy, and frozen food. With the cold chain remaining satisfied, there will be less damage in transportation.

Example: A grocery supermarket uses environmental sensors inside refrigerated trucks that transport fresh produce. During one delivery run to one store, one of the environmental sensors determined that the temperatures were rising because of a malfunction in the cooling system. The system sent a notification, and the truck was sent to be turned into a repair shop in the nearest town before the produce could spoil; it thus saved thousands of dollars for the supermarket.

Use Case: Long-Haul Trucks Environmental Air Quality Monitoring

Environmental sensors can track the air quality inside the cabin of the vehicle for the purpose of maintaining the health and comfort of the drivers as they spend long haul times in which cabin conditions may deteriorate.

Example: A logistics firm has installed air quality sensors in its long-haul trucks. These sensors measure levels of CO2 and other harmful gases in the cabin. One day, a truck suddenly reads the level of CO2 to be highly astronomical, meaning there is a ventilation problem. The system shows the driver a message to stop and attend to the matter, thereby saving him from possible driver fatigue or even health complications.

Conclusion

Sensor technology does not only bring in real-time tracking with optimized fuel consumption in fleet management but also predictive maintenance and safety both for drivers and cargo. All these features, besides being more efficient in operational efficiency, also turn out to be cost-effective, with no accidents and compliance with industry standards. Using it with proper insight, hence, will enable companies to advance more conveniently within the industry with this.